Our mobile solutions ensure the mobile production, distribution, and connection of ozone. The systems cleanse and disinfect tanks, closed piping systems, machines, and equipment in an efficient and environmentally friendly manner.

Approved by the Norwegian Medicines Agency and the Food Safety Authority as a disinfectant in the aquaculture industry.

Ozone production occurs on-site when you need it, eliminating all logistics related to the purchase, storage, and handling of chemicals.

We have three different mobile solutions that can be tailored to various needs. These are also perfect for pilot projects and smaller facilities.

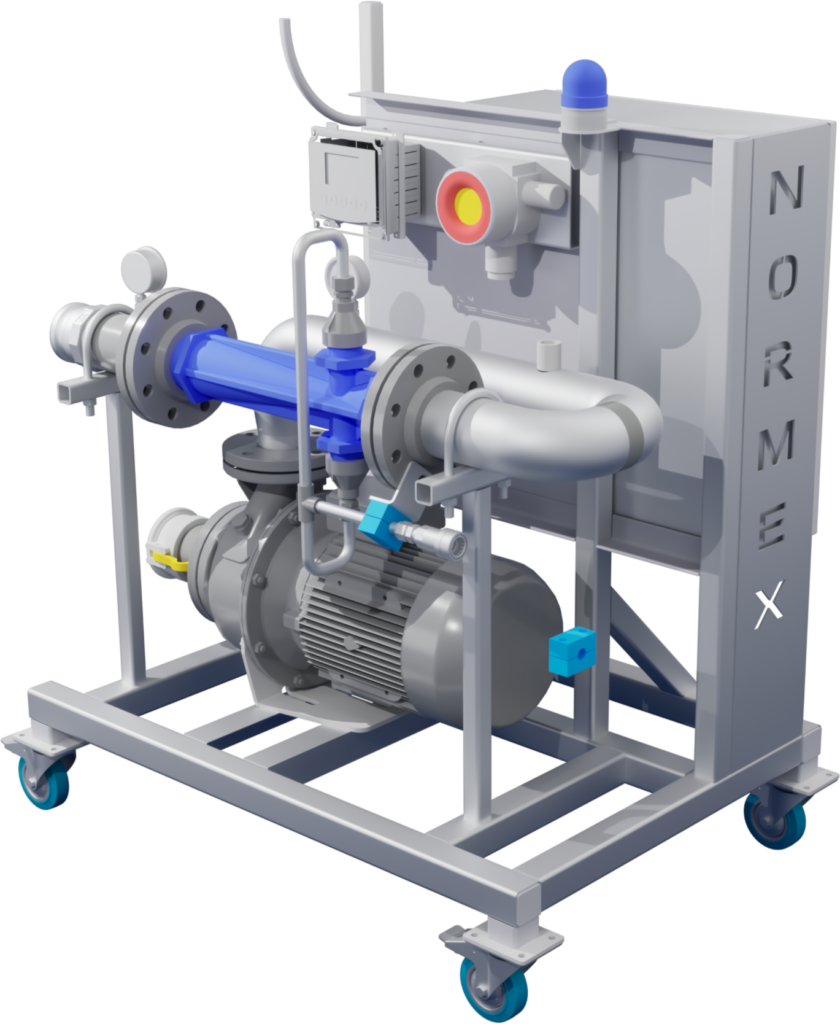

The ozone production unit is permanently located, with distribution pipes leading to each tank and potentially to various departments. A shared mobile injection skid is used, which can be moved around to connect to each individual tank that needs treatment.

This is an efficient method for ensuring both biosecurity and production at the facility without the use of chemicals. The Ozone Injector Skid is also perfectly suited for retrofitting existing facilities.

The Ozone Skid is our latest development in disinfection technology, designed to deliver powerful and effective cleaning for land-based aquaculture facilities.

The mobile unit is fully equipped to produce ozone on-site, making it suitable for use at multiple facilities.

It is easy to move the entire module with a pallet jack or forklift, providing great flexibility to meet unique disinfection needs wherever they arise.

In this solution, ozone production takes place in a container that is permanently installed at the facility but can be moved if necessary.

This is a simple “add-on solution” for existing facilities, but it can also be mounted on a service boat, barge, or similar vessel.

It offers advantages such as:

The facility is delivered fully built, tested and configured. It only requires connection to power, water, and the process system – enabling rapid start-up.

It requires minimal assembly and no extensive on-site construction, significantly reducing the overall project execution time.

All assembly and testing are carried out under controlled factory conditions, ensuring high and fully documented quality.

The container integrates the entire ozone facility into a single unit – ideal where space is limited or existing buildings are unavailable.

It can be installed outdoors, indoors, or at temporary locations, and can easily be relocated as needs change.

The container can be relocated or reused to accommodate changing production needs or new sites.

Multiple containers can be interconnected to increase capacity or redundancy.

The container provides mechanical protection and can be adapted for demanding environments, such as climate, corrosion, ATEX and noise limitations.

Integrated safety systems, ventilation, and gas detection are fully engineered and installed.

Lower installation costs, shorter project timelines, and reduced need for on-site adaptations result in a favourable TCO.

Standardised, pre-engineered solution ensures better cost control and predictable delivery.

Good accessibility to components and a standardised setup enable efficient operation and service.

Our mobile solutions for water treatment and disinfection can be used for land-based aquaculture facilities, closed fish farms at sea, fishing boats, well boats and processing plants.