EFFECTIVE: ‘We immediately saw that the ozone system effectively dissolved particles, removed biofilm, and cleaned growth in ways that chemicals could never achieve,’ says Einar Nesse Johnsen, CEO of Hjelvik Matfisk.’

Hjelvik Matfisk was among the first in the world to adopt a flow-through system for land-based salmon farming. Now, they are seeing promising results with disinfection technology from Normex.

‘One of the major challenges in the aquaculture industry is salmon lice. The industry spends billions of NOK trying to combat it. The best solution currently is to keep the fish on land as long as possible, and that’s what we’re doing,’ says Einar Nesse Johnsen, CEO of the land-based aquaculture company Hjelvik Matfisk.

Located in Vågstranda, Rauma, right next to Hjelvik Settefisk, the company aims to minimise the time farmed salmon spend at sea.

‘By reducing the time salmon are in the ocean, we contribute to lower lice infestations, giving the lice minimal time to attach before the fish are harvested,’ Johnsen explains.

A pilot project

Hjelvik Matfisk, operational since 2022, was one of the first in the world to establish a dedicated flow-through system for land-based salmon farming for food fish. This allows them to produce both post-smolt up to one kilogram and fully grown salmon ready for consumption.

The company holds a license to produce 2,000 tons of fish annually and is in the first phase of a larger expansion plan. Johnsen describes the company as a pilot project for now:

‘We are currently familiarising ourselves with the production process and the challenges that need to be addressed. Over time, we plan to build more tanks in the area.’

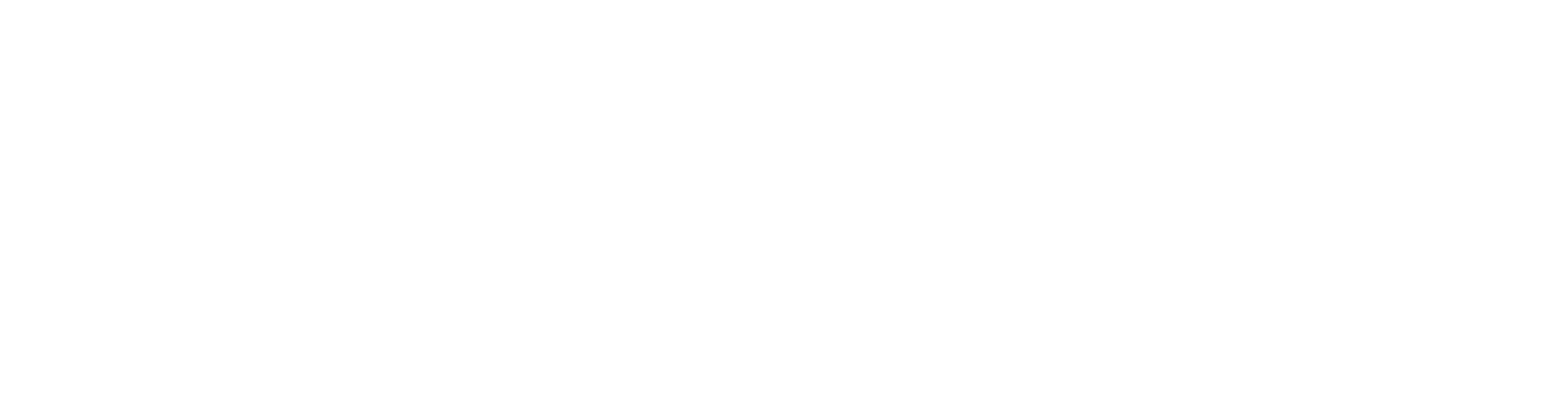

COMBATING DISINFECTION: Hjelvik Matfisk is pleased with Normex’s mobile disinfection technology, Ozone Skid. It delivers powerful and effective cleaning for land-based aquaculture facilities.

Disinfection challenges

This autumn, Hjelvik Matfisk installed Normex’s mobile disinfection technology, the Ozone Skid. Designed to deliver powerful and effective cleaning for land-based aquaculture facilities. The mobile unit is fully equipped to produce ozone on-site, making it suitable for use at multiple facilities.

The company turned to Normex due to difficulties with disinfection.

‘We don’t have lice in our facilities, but environmental bacteria pose a threat by establishing themselves on inaccessible surfaces in tanks, valves, and piping systems, potentially leading to wounds and diseases in the fish.’

Before contacting Normex, the company tested several solutions.

‘We tried chemicals and various UV treatments to eliminate the bacteria, but without success.’

Environmentally friendly alternative to chemicals

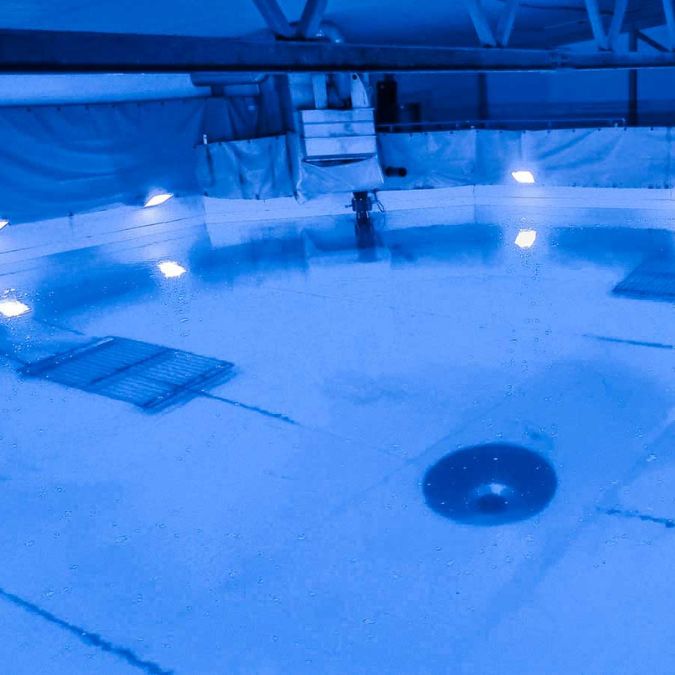

Recently, Hjelvik Matfisk completed its first disinfection round using the new ozone system, which they utilise between each stocking of fish.

‘We immediately saw that the ozone system effectively dissolved particles, removed biofilm, and cleaned growth in ways that chemicals could never achieve. Ozone is also a much more efficient and environmentally friendly alternative to chemicals,’ Johnsen states.

‘Other advantages?’

‘We can now extend the disinfection process over a longer period. Previously, we had to complete it in just a few hours, but now we can do it over several days. We now continuously add a small amount of ozone to the water when disinfecting between each stocking. This provides greater security and reduces the risk of bacterial ‘house strains’ developing,’ he elaborates.

‘The ozone system enhances biosecurity between fish cycles by removing bacteria that were previously hard to reach. We are also better prepared in case of outbreaks of serious listed diseases where the Norwegian Food Safety Authority (Mattilsynet) requires disinfection,’ he adds.

Previously, Hjelvik Matfisk faced significant expenses trying to combat bacteria – costs that are now being significantly reduced.

‘Based on our previous disinfection costs, we estimate that we can pay off this ozone system within five years.’

INCREASED SECURITY: The ozone system enhances biosecurity between fish cycles by removing bacteria that were previously hard to reach.

Ensure mobile production

Michael Vadseth, Sales Manager at Normex, is pleased with the results at Hjelvik Matfisk. The solution used is one of three different mobile solutions by Normex that can be tailored to various needs.

‘Our mobile solutions ensure the mobile production, distribution, and connection of ozone. The systems cleanse and disinfect tanks, closed piping systems, machines, and equipment in an efficient and environmentally friendly manner. It is easy to move the entire Ozone Skid module with a pallet jack or forklift, providing great flexibility to meet unique disinfection needs wherever they arise,’ says Vadseth.

Normex Desinfecta is approved by the Norwegian Medicines Agency and the Food Safety Authority as a disinfectant in the aquaculture industry.